Notes on PETG+CF filaments

In this article, you will find information on the technical parameters of PETG+CF filaments and tips on choosing the right material for printing astrophotography accessories.

There are many filaments labeled as PETG+CF available on the market. They often differ from each other even if they have the same carbon fiber content. Two filaments from different brands may be labeled PETG+CF 10 (meaning 10% carbon fiber added) and yet differ significantly in their properties. In particular, one may be very stiff and the other soft, with a matte appearance, not much different from regular PETG. It even happens that a filament of one brand with 15% carbon fiber admixture will be less rigid than a filament of another brand with 10% admixture.

Why?

Assuming that the manufacturer provides accurate information, there are two main reasons for these differences.

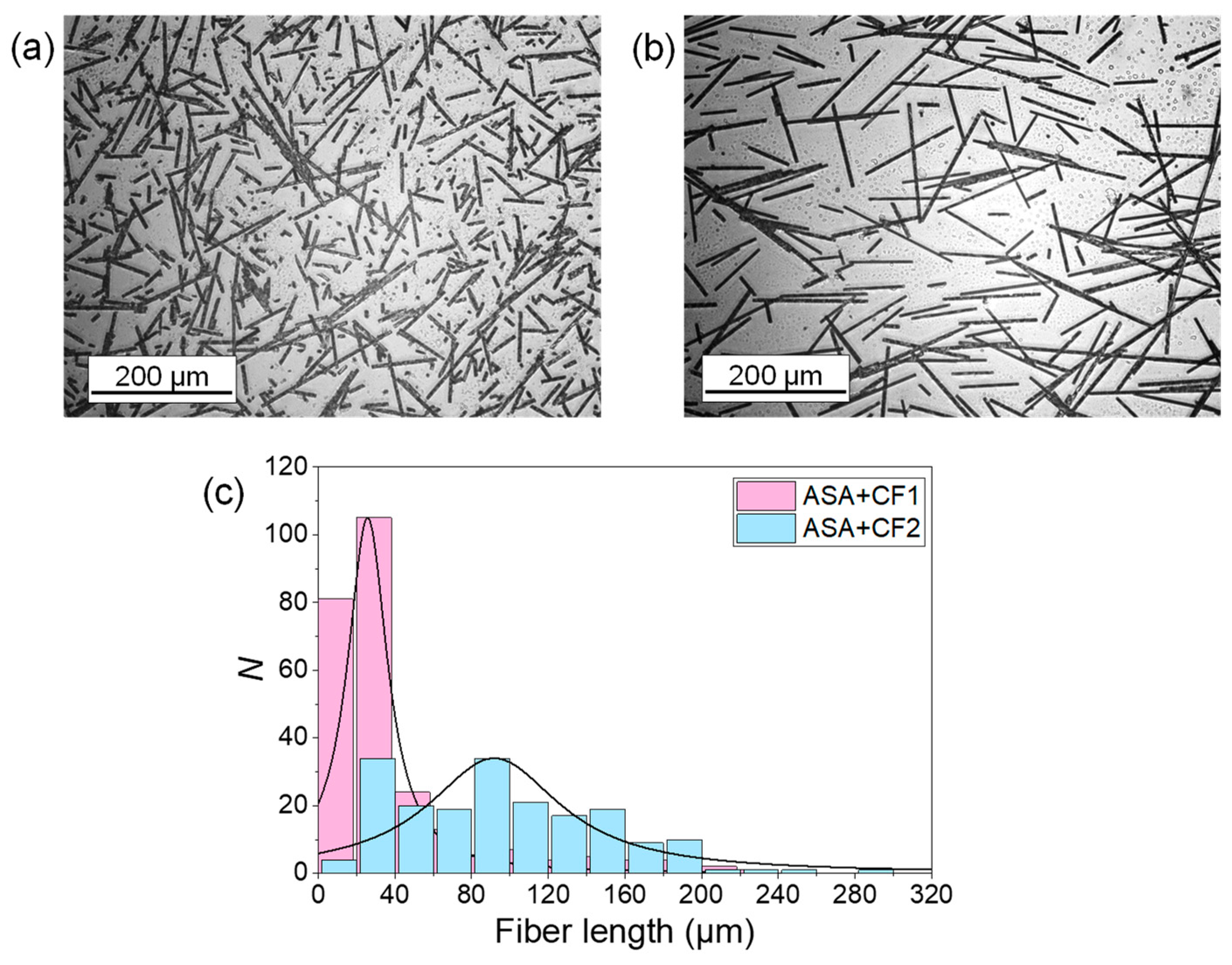

The first reason is the length of the added fibers. The longer the fibers, the stiffer the print. Two filaments may have the same percentage of additive, but one will have something more like carbon dust added, while the other will have solid, long pieces of carbon fiber. This obviously translates into the mechanical parameters of the printed model, which is clearly visible in an independent study testing ASA mixed with carbon fiber.

Most often, you can be almost certain that the cheapest filaments are the worst in this respect. The prints may look beautiful, but their rigidity leaves much to be desired.

Only good-quality, honestly mixed filaments with long carbon fibers ensure adequate stiffness and low shrinkage during printing. For astrophotography, dimensional accuracy is critically important, so it is worth investing in a good engineering-grade filament.

The second reason is other “refining” additives to the filament.

Most manufacturers add additional chemical compounds to PETG to stabilize it, facilitate printing, or achieve other desired parameters, such as visual ones. The presence of these compounds can significantly affect the mechanical parameters of the filament, and the manufacturer rarely discloses the full composition, even in the TDS sheet.

So how do you choose a good PETG+CF filament?

Unfortunately, the only good way is trial and error. However, to increase the likelihood of making the right choice, it is worth following a few tips:

-

Do not choose the cheapest filaments. Users may even praise them, but keep in mind that they often evaluate the ease of printing and its aesthetics rather than the mechanical parameters. So aim for filaments starting at around half the average market price. Choose well-known brands with an established reputation for quality.

-

Ask the seller to send you samples or, if this is not possible, start with the smallest spool. Evaluate the appearance. Filament with long fibers has a rough surface, slightly iridescent, sometimes looking as if it were carved.

-

Make a test print using well-dried filament. The surface should be delicately rough, definitely not slippery.

-

Perform a mechanical test using a caliper:

-

Download FTM test model for printing.

-

3D-print the model using PETG+CF filament and 100% infill.

-

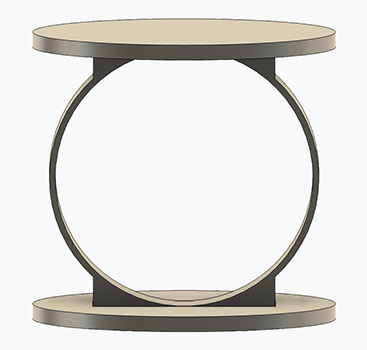

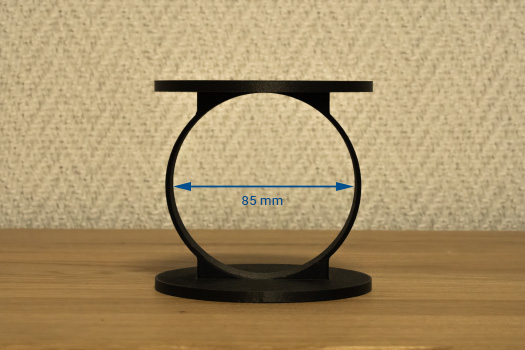

Assemble it using cyanoacrylate glue, sticking the top and bottom trays to a vertical circle. This is what the final result should look like:

Fig.2 - Assembled test model -

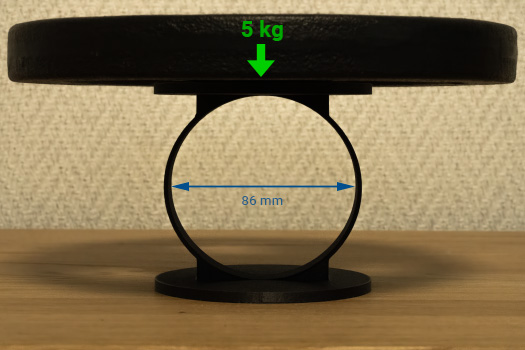

Place the test model on a table and load it with a weight of 5 kg. You can use a pot filled with 5 liters of water for this, but in any case, ask another person to help you and secure the weight so that it does not fall off the wobbly base during measurement.

-

Measure the transverse dimension of the rim under load. If the filament is of good mechanical quality, the width of the internal transverse diameter should be about 86 mm. In other words, under the pressure of a 5 kg weight, the rim should expand by more-less 1 mm.

-

"

"

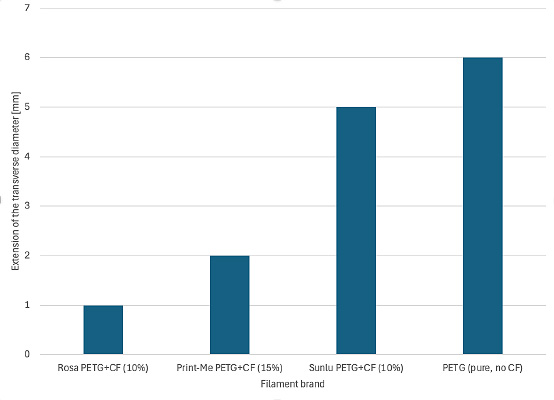

The chart below presents the results of an experiment I conducted on four different filaments commonly available in Poland. The best result was achieved by Rosa PETG+CF filament doped with 10% carbon fiber.

Please note that although the next filament according to the specifications has 15% carbon fiber, it is more flexible than its predecessor. Sunlu, on the other hand, which has 10% carbon fiber in its specifications, is almost as flexible as pure PETG.

"

"

The results clearly show that when choosing a filament, you cannot be guided by what is written on the box or even in the TDS sheet. The best filament for 3D printing, especially in the case of such a demanding engineering material as PETG+CF, should be selected by testing and checking the actual mechanical properties of the printed models.

Sources:

- Burgos Pintos, P., Moreno Sánchez, D., Delgado, F. J., Sanz de León, A., & Molina, S. I. (2024). Influence of the Carbon Fiber Length Distribution in Polymer Matrix Composites for Large Format Additive Manufacturing via Fused Granular Fabrication. Polymers, 16(1), 60. https://doi.org/10.3390/polym16010060